SENSE ALL.

Data and information are all around us and the potential to harvest them is broad. We are focused on providing modern, reliable and cost-reducing solutions and products for that purpose. Our special expertise are systems under pressure. We aim towards lowering the total costs of systems maintenance by applying complete, reliable, and cost-reducing solutions.

Contact UsAbout Us

SENSOL-Tech is a tech company based in Zagreb, Croatia (EU). We are an innovative company with strong manufacturing support. Our focus is to bring traditional industry applications and equipment to a new, digital, and modern era. Using our experience and expertise from more than 30 years in the industry, especially in the process and power industry, we apply cutting-edge Technologies and smart solutions to standard industrial products.

Become a well-known and respected brand in the field of smart, innovative, and reliable products and solutions for industrial applications.

To use gathered knowledge and experience and provide simple, reliable, and smart solutions and products to the industry.

Responsibility, innovation and creativity, flexibility, quality and expertise, safety and reliability, sustainability, customer oriented.

Smart ENergy SOLutions & Technologies

SENSOL-Tech is a derivative out of Smart ENergy SOLutions & Technologies that fully conveys the intention, direction, and purpose of the company. Full emphasis is placed on smart products for various process monitoring, as well as on individual parts of standard industrial equipment that require rework, either at the customer’s request, or at the request of the industry itself. Using our many years of experience in the industry and gathered knowledge we want to modernize the traditional ways.

Based in Croatia (EU)

+30 years of experience

Smart

solutions

Strong production background

Industries and applications

Our broad range of products is specially designed to cover multiple industries and applications. We are present and experienced in some of them for more than 30 years, like the Oil&Gas and Power industry. Some niche industries are now becoming more relevant like the Hydrogen industry, Offshore and Process Monitoring.

Our emphasis is on oil-filled Transformers and their standard equipment, and single-gas DGA devices.

Implementing various measuring devices that simplify maintenance procedures and provide reliable process monitoring data.

Monitoring of various physical properties of the medium in pipelines under pressure with an accent on safety, reliability and repeatability.

We are active participants in relevant organizations regarding hydrogen production, its use and monitoring. Our sensors for hydrogen have various applications like safety, optimization, and detection. They are optimized for long-life (+10years) use and are auto-calibrating, so maintenance free.

Our products are well suited for offshore anti-corrosion conditions and we are certified to perform various on-site actions (maintenance, installation, retrofitting).

We offer various dimensions of machined ultra-pure ESR steel blocks from our partner www.armature.ba

Products and solutions

By extensively analysing the market, we carefully divided our product portfolio into Smart products for general industrial use and Transformer accessories. All of our products are supported by our aftersales service and maintenance team as well as with the first installation and retrofitting on-site installation options.

- Smart products

- Transformer accessories

- Installation, service and maintanence

-

SENSOL DGM-1

Direct-in-oil DGA sensor for Hydrogen (H2)

-

SENSOL DGM-2

Online DGA monitor for Hydrogen (H2) and Moisture

-

IOT pressure tracking module

Pressure maintaining device with IOT pressure tracking module

-

Moisture-in-oil and temperature transmitter

-

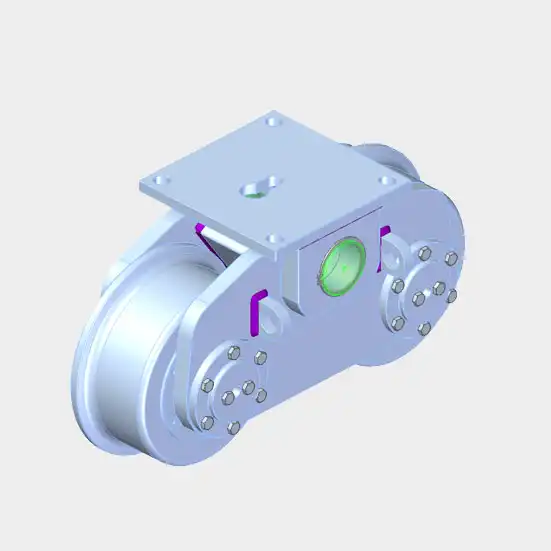

Transformer wheels acc. to DIN

25, 50, 70, 75, 100 tons of load capacity, welded acc. to DIN 3834-2

-

Flexible braided connectors

Flexible copper braided current and grounding connectors

-

Bushing connection flags acc. to DIN 43675

Customizable bushing connection flags acc. to DIN 43675 –drilling and threads on request

-

Steel and aluminum enclosures

Dimensions on request, powder coated, minimum IP65 protection, A4 fasteners

-

Metal energy service team

Industrial service and maintenance, spare parts and repairment, installation, testing, supervision and consulting

-

Metal energy service team

Quick response and 24/7 availability service@metal-energy.com

-

Metal energy service team

Our service technicians have valid safety certificates and are well suited and equipped for various on-site interventions

-

Metal energy service team

Our team is present on many industrial sites including refineries, power plants, pipelines, LNG terminals, offshore platforms, wind farms, …

Technical data sheets

For all of our serial product solutions, here you can download the last editions of technical data sheets (TDS) to find more specific information.

DGA sensor for Hydrogen

Online DGA monitor for Hydrogen and Moisture

R&D Center

We see enormous growth in the demand for process monitoring and prediction of process behaviour. Also, there is a great focus on reducing system maintenance costs, especially for those in remote and hard-to-reach locations.

Given the vast production support and capacity, and together with our commercial and R&D centre in Zagreb, Croatia, we are open to providing customized solutions to every part of the industry.

We collaborate with various experts and institutions and keep up with the trends and needs of the market.

In the first few initial meetings, we are working with our client on fully defining the request. With that information, we proceed on analyzing many different options with the goal of providing several reliable, simple, and adequate solutions to fit client needs. We are constantly working with experts and reliable institutions to easily identify and follow industry trends and their possibility of implementation. When the client makes a choice on the final solution, we proceed to the next step.

In the design phase, we are using computer-aided design software, supported by calculations and process simulations to predict real-use experience conditions. The prototype phase usually consists of several versions of the final product which we test according to all specified standards, and our in-house normative. During this process, we make iterations until the final product is ready for installation as per the client’s full initial needs.

We offer full installation and aftersales service for all of our product ranges and solutions. Installation can be arranged in-house or on-site, as well as on brand-new units, but also with an option of retrofit on older ones.

Get In Touch

Please contact us directly for any additional question or inquiry!